Description

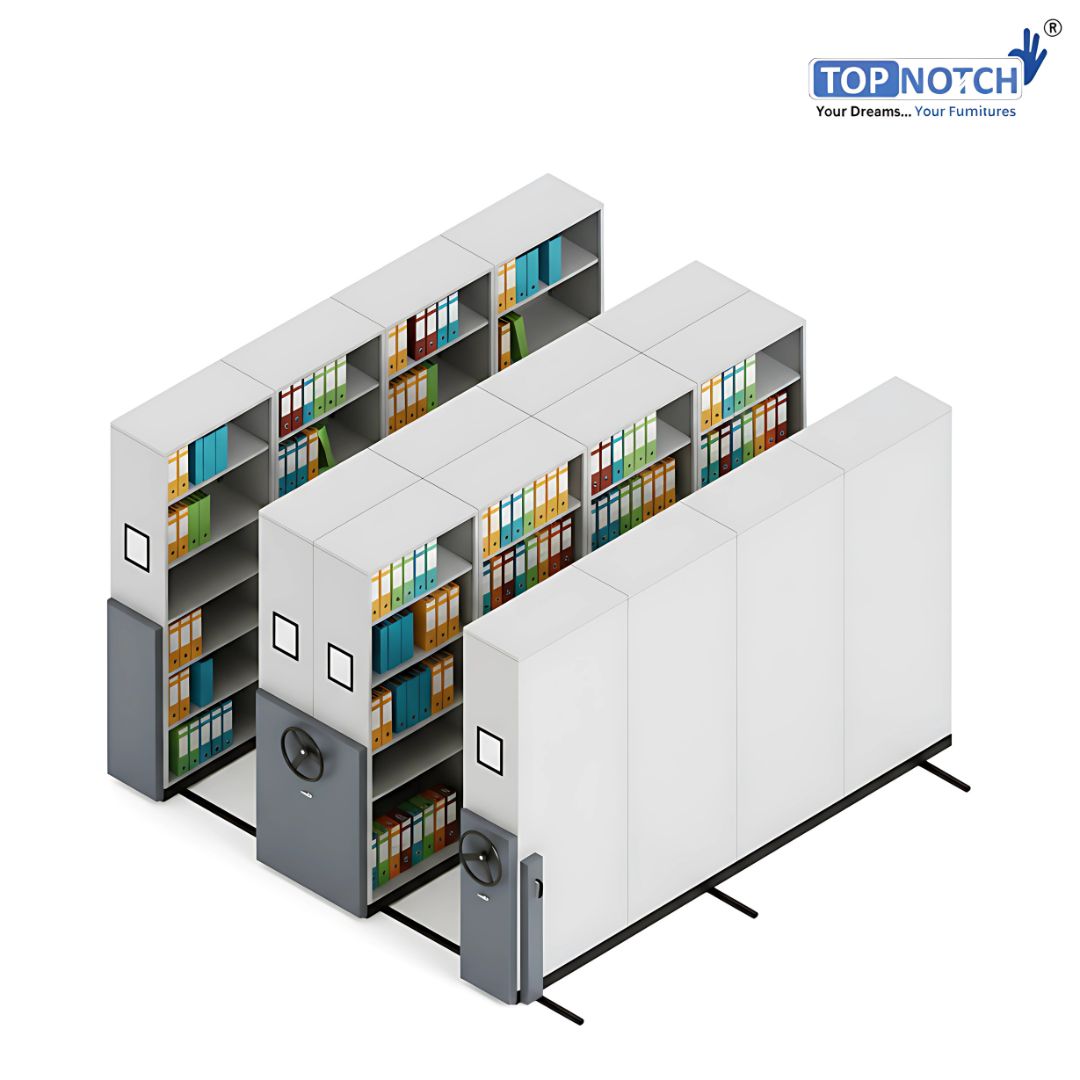

The Topnotch 4 Bay – 16 Bodies Mobile Storage Compactor (Non-Standard) is a next-generation filing and record storage solution designed for organizations that require high-capacity, space-efficient, and secure storage. Unlike conventional racks and almirahs, this compactor system reduces aisle requirements and maximizes usable storage density, making it ideal for offices, banks, hospitals, universities, government departments, archives, and industrial setups.

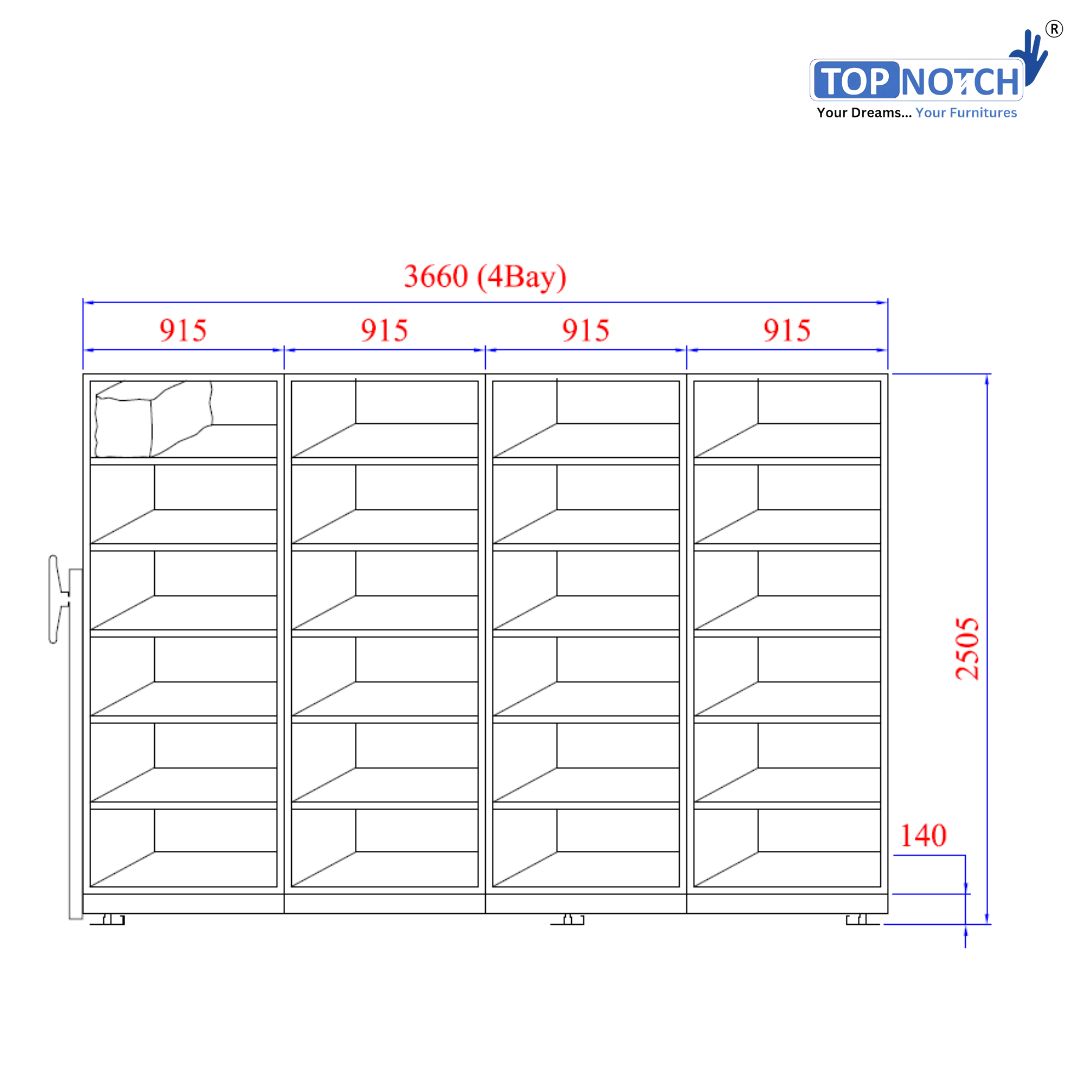

Each body measures 2505 mm (H) × 915 mm (W) × 450 mm (D) — taller than standard compactors, providing additional storage per cabinet. The 5 adjustable/removable shelves per body create 6 usable compartments per cabinet, offering flexibility to store different file types, from thin office files to bulky box files and ledgers.

The 4 Bay – 16 Body compactor includes:

-

1 SFF (Single Fixed Frame) → static, one side open.

-

Multiple DFM (Double-Faced Movable Frames) → open on both sides, movable.

-

1 SFM (Single-Faced Movable Frame) → one side open, movable.

Together, these make up 16 full-size cabinets (bodies), which can store up to 1248 box files OR 2400 thin files in an optimized footprint.

Superior Build Quality

The compactor is made using 0.8 mm CRCA steel sheet (IS: 513, D Grade, TATA/JSW make), ensuring structural strength and long-lasting durability. The base frame is crafted with 3.15 mm HR sheet (IS 2062 / IS 1079), providing a rock-solid foundation to handle heavy loads.

The entire system is treated with an 8-tank anti-rust process, followed by epoxy polyester powder coating (40–70 microns) for corrosion resistance, scratch resistance, and an elegant dual-tone finish.

Drive System

The mechanical chain & sprocket drive system ensures effortless movement of even fully loaded units. Built with Diamond brand ½” chain, 20 mm steel shafts, heavy-duty sprockets, pedestal bearings, and 90 × 32 mm CI wheels, the system operates smoothly and vibration-free.

Safety & Security

-

Anti-topple mechanism ensures stability.

-

Anti-skid rails keep cabinets aligned.

-

Centralized locking protects confidential files.

-

Indexing provision with metal plates improves file retrieval.

Installation & Support

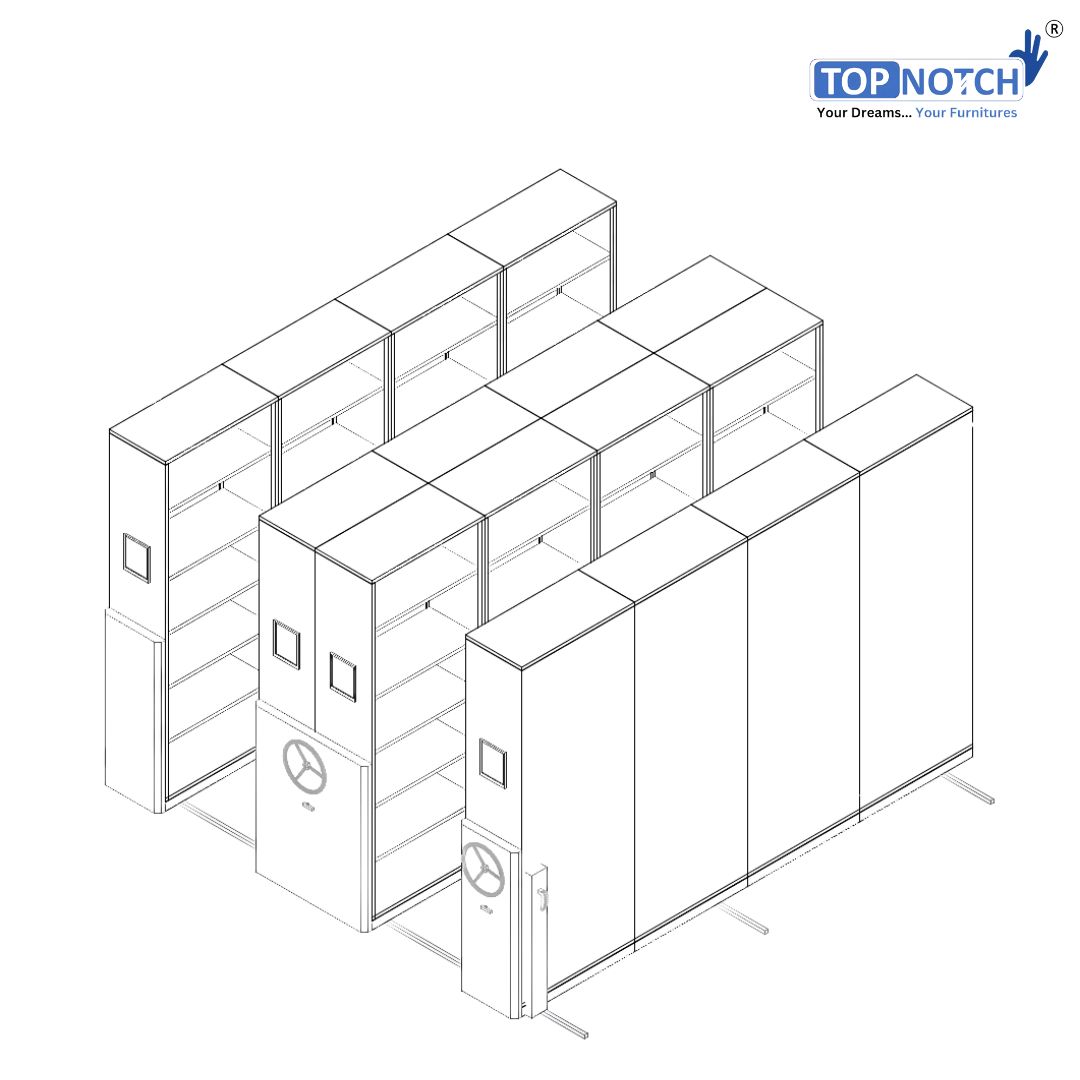

The compactor follows a knock-down modular design with weldless clinch joints, making installation fast and hassle-free. CAD layout planning ensures precision, and professional installation is provided on-site.

With PAN India delivery, AMC availability, and GEM portal registration, Topnotch ensures smooth procurement and long-term service support.

👉 In short: The Topnotch 4 Bay – 16 Bodies Mobile Storage Compactor (Non-Standard) is a high-capacity, durable, and space-saving file storage system that replaces 16 traditional almirahs with a modern, professional solution.

Key Advantages

-

Saves 50–60% more space compared to traditional racks/almirahs.

-

Heavy-duty storage with high load-bearing shelves.

-

Smooth & safe mechanical drive with anti-topple design.

-

Dual security system – centralized & individual locks.

-

Premium powder coating for corrosion resistance & aesthetics.

-

Suitable for files, records, archives, spare parts, and warehouse storage.

Comparison: Mobile Storage Compactor (4 Bay – 16 Bodies) vs. Traditional 16 Almirahs

| Parameter | Mobile Storage Compactor – 4 Bay 16 Bodies | Traditional 16 Standard Almirahs |

|---|---|---|

| Space Utilization | Occupies ~40–50% less floor space due to single working aisle | Requires dedicated aisle space in front of each almirah, consuming more area |

| Storage Capacity | 16 Bodies × 5 Compartments = 80 Compartments | 16 Almirahs × 5 Compartments = 80 Compartments |

| Load Capacity | 60–70 Kg per shelf × 80 shelves = 3840–4480 Kg UDL | 60–70 Kg per shelf × 80 shelves = 3840–4480 Kg UDL |

| Accessibility | Smooth mechanical chain & sprocket system allows easy movement of bays | Manual opening/closing of each almirah, requires more physical effort |

| Aisle Requirement | Only 1 aisle (760 mm / 2.5 ft) needed for full system | 16 aisles needed (one per almirah), wasting significant floor area |

| Security | Centralized + Individual Locking (3-way lock system) | Individual locks only, harder to manage securely |

| Safety Features | Anti-topple, vibration-free, rubber/PVC studs for noise reduction | No anti-topple protection, higher chance of imbalance |

| Durability | Weldless clinch-joint design, 0.8 mm CRCA sheet, 8-tank anti-rust treatment | Varies by manufacturer, generally less rigid & prone to rust over time |

| Aesthetics | Dual-tone epoxy polyester powder coating (40–70 microns) | Basic paint or powder coating, limited finishes |

| Installation | CAD layout + professional installation, modular knock-down design | Simple placement, but non-modular and bulky |

| Maintenance | Easy to service with AMC & after-sales support | Limited service support, depends on vendor |

| Space Saving | Saves up to 50–60% floor space compared to almirahs | Consumes ~2X more space due to multiple aisles |

| Best Suited For | Offices, banks, archives, warehouses with large record storage needs | Small offices or spaces with limited filing needs |

-

Both systems have similar storage capacity, but the Mobile Storage Compactor provides up to 60% space savings, better security, centralized control, and professional-grade durability.

-

Traditional almirahs are cheaper initially but inefficient in terms of space, security, and long-term usability.

-

For organizations with large records, files, or parts storage needs, the Mobile Compactor is the clear winner.

Product Highlights / Bullet Points

-

High Storage Capacity – 16 Bodies × 5 Compartments = 80 Compartments, each shelf supports 60–70 Kg UDL.

-

Heavy-Duty Construction – Made from 0.8 mm CRCA Steel (TATA/IS 513 D Grade) with weldless clinch-joint design for long durability.

-

Space-Saving Optimizer – Requires only 1 aisle (2.5 ft), saving up to 60% floor space compared to traditional racks/almirahs.

-

Smooth Operation – Mechanical chain & sprocket system with antifriction bearings and CI wheels for effortless movement.

-

Enhanced Safety & Security – Equipped with 3-way centralized + individual locking system, anti-topple design & rubber studs for noise-free operation.

-

Superior Finish – 8-tank anti-rust treatment with epoxy polyester powder coating (40–70 microns), available in dual-tone colors.

-

Modular & Easy Installation – CAD layout planning, knock-down structure, professional on-site assembly.

-

Multi-Sector Use – Ideal for corporates, banks, insurance companies, government offices, hospitals, warehouses, universities & archives.

-

Certifications – ISO 9001, ISO 14001, ISO 45001, ISO 50001, BIFMA, GREENGUARD certified for quality, durability & sustainability.

-

After-Sales Support – PAN India delivery, AMC & service support available.

Reviews

There are no reviews yet.